|

| August 28, 2012 | Volume 08 Issue 32 |

Electrical/Electronic News & Products

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Intro to reed switches, magnets, magnetic fields

This brief introductory video on the DigiKey site offers tips for engineers designing with reed switches. Dr. Stephen Day, Ph.D. from Coto Technology gives a solid overview on reed switches -- complete with real-world application examples -- and a detailed explanation of how they react to magnetic fields.

This brief introductory video on the DigiKey site offers tips for engineers designing with reed switches. Dr. Stephen Day, Ph.D. from Coto Technology gives a solid overview on reed switches -- complete with real-world application examples -- and a detailed explanation of how they react to magnetic fields.

View the video.

Bi-color LEDs to light up your designs

Created with engineers and OEMs in mind, SpectraBright Series SMD RGB and Bi-Color LEDs from Visual Communi-cations Company (VCC) deliver efficiency, design flexibility, and control for devices in a range of industries, including mil-aero, automated guided vehicles, EV charging stations, industrial, telecom, IoT/smart home, and medical. These 50,000-hr bi-color and RGB options save money and space on the HMI, communicating two or three operating modes in a single component.

Created with engineers and OEMs in mind, SpectraBright Series SMD RGB and Bi-Color LEDs from Visual Communi-cations Company (VCC) deliver efficiency, design flexibility, and control for devices in a range of industries, including mil-aero, automated guided vehicles, EV charging stations, industrial, telecom, IoT/smart home, and medical. These 50,000-hr bi-color and RGB options save money and space on the HMI, communicating two or three operating modes in a single component.

Learn more.

All about slip rings: How they work and their uses

Rotary Systems has put together a really nice basic primer on slip rings -- electrical collectors that carry a current from a stationary wire into a rotating device. Common uses are for power, proximity switches, strain gauges, video, and Ethernet signal transmission. This introduction also covers how to specify, assembly types, and interface requirements. Rotary Systems also manufactures rotary unions for fluid applications.

Rotary Systems has put together a really nice basic primer on slip rings -- electrical collectors that carry a current from a stationary wire into a rotating device. Common uses are for power, proximity switches, strain gauges, video, and Ethernet signal transmission. This introduction also covers how to specify, assembly types, and interface requirements. Rotary Systems also manufactures rotary unions for fluid applications.

Read the overview.

Seifert thermoelectric coolers from AutomationDirect

Automation-Direct has added new high-quality and efficient stainless steel Seifert 340 BTU/H thermoelectric coolers with 120-V and 230-V power options. Thermoelectric coolers from Seifert use the Peltier Effect to create a temperature difference between the internal and ambient heat sinks, making internal air cooler while dissipating heat into the external environment. Fans assist the convective heat transfer from the heat sinks, which are optimized for maximum flow.

Automation-Direct has added new high-quality and efficient stainless steel Seifert 340 BTU/H thermoelectric coolers with 120-V and 230-V power options. Thermoelectric coolers from Seifert use the Peltier Effect to create a temperature difference between the internal and ambient heat sinks, making internal air cooler while dissipating heat into the external environment. Fans assist the convective heat transfer from the heat sinks, which are optimized for maximum flow.

Learn more.

EMI shielding honeycomb air vent panel design

Learn from the engineering experts at Parker how honeycomb air vent panels are used to help cool electronics with airflow while maintaining electromagnetic interference (EMI) shielding. Topics include: design features, cell size and thickness, platings and coatings, and a stacked design called OMNI CELL construction. These vents can be incorporated into enclosures where EMI radiation and susceptibility is a concern or where heat dissipation is necessary. Lots of good info.

Learn from the engineering experts at Parker how honeycomb air vent panels are used to help cool electronics with airflow while maintaining electromagnetic interference (EMI) shielding. Topics include: design features, cell size and thickness, platings and coatings, and a stacked design called OMNI CELL construction. These vents can be incorporated into enclosures where EMI radiation and susceptibility is a concern or where heat dissipation is necessary. Lots of good info.

Read the Parker blog.

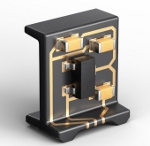

What is 3D-MID? Molded parts with integrated electronics from HARTING

3D-MID (three-dimensional mechatronic integrated devices) technology combines electronic and mechanical functionalities into a single, 3D component. It replaces the traditional printed circuit board and opens up many new opportunities. It takes injection-molded parts and uses laser-direct structuring to etch areas of conductor structures, which are filled with a copper plating process to create very precise electronic circuits. HARTING, the technology's developer, says it's "Like a PCB, but 3D." Tons of possibilities.

3D-MID (three-dimensional mechatronic integrated devices) technology combines electronic and mechanical functionalities into a single, 3D component. It replaces the traditional printed circuit board and opens up many new opportunities. It takes injection-molded parts and uses laser-direct structuring to etch areas of conductor structures, which are filled with a copper plating process to create very precise electronic circuits. HARTING, the technology's developer, says it's "Like a PCB, but 3D." Tons of possibilities.

View the video.

Loss-free conversion of 3D/CAD data

CT CoreTech-nologie has further developed its state-of-the-art CAD converter 3D_Evolution and is now introducing native interfaces for reading Solidedge and writing Nx and Solidworks files. It supports a wide range of formats such as Catia, Nx, Creo, Solidworks, Solidedge, Inventor, Step, and Jt, facilitating smooth interoperability between different systems and collaboration for engineers and designers in development environments with different CAD systems.

CT CoreTech-nologie has further developed its state-of-the-art CAD converter 3D_Evolution and is now introducing native interfaces for reading Solidedge and writing Nx and Solidworks files. It supports a wide range of formats such as Catia, Nx, Creo, Solidworks, Solidedge, Inventor, Step, and Jt, facilitating smooth interoperability between different systems and collaboration for engineers and designers in development environments with different CAD systems.

Learn more.

Top 5 reasons for solder joint failure

Solder joint reliability is often a pain point in the design of an electronic system. According to Tyler Ferris at ANSYS, a wide variety of factors affect joint reliability, and any one of them can drastically reduce joint lifetime. Properly identifying and mitigating potential causes during the design and manufacturing process can prevent costly and difficult-to-solve problems later in a product lifecycle.

Solder joint reliability is often a pain point in the design of an electronic system. According to Tyler Ferris at ANSYS, a wide variety of factors affect joint reliability, and any one of them can drastically reduce joint lifetime. Properly identifying and mitigating potential causes during the design and manufacturing process can prevent costly and difficult-to-solve problems later in a product lifecycle.

Read this informative ANSYS blog.

Advanced overtemp detection for EV battery packs

Littelfuse has introduced TTape, a ground-breaking over-temperature detection platform designed to transform the management of Li-ion battery systems. TTape helps vehicle systems monitor and manage premature cell aging effectively while reducing the risks associated with thermal runaway incidents. This solution is ideally suited for a wide range of applications, including automotive EV/HEVs, commercial vehicles, and energy storage systems.

Littelfuse has introduced TTape, a ground-breaking over-temperature detection platform designed to transform the management of Li-ion battery systems. TTape helps vehicle systems monitor and manage premature cell aging effectively while reducing the risks associated with thermal runaway incidents. This solution is ideally suited for a wide range of applications, including automotive EV/HEVs, commercial vehicles, and energy storage systems.

Learn more.

Benchtop ionizer for hands-free static elimination

EXAIR's Varistat Benchtop Ionizer is the latest solution for neutralizing static on charged surfaces in industrial settings. Using ionizing technology, the Varistat provides a hands-free solution that requires no compressed air. Easily mounted on benchtops or machines, it is manually adjustable and perfect for processes needing comprehensive coverage such as part assembly, web cleaning, printing, and more.

EXAIR's Varistat Benchtop Ionizer is the latest solution for neutralizing static on charged surfaces in industrial settings. Using ionizing technology, the Varistat provides a hands-free solution that requires no compressed air. Easily mounted on benchtops or machines, it is manually adjustable and perfect for processes needing comprehensive coverage such as part assembly, web cleaning, printing, and more.

Learn more.

LED light bars from AutomationDirect

Automation-Direct adds CCEA TRACK-ALPHA-PRO series LED light bars to expand their offering of industrial LED fixtures. Their rugged industrial-grade anodized aluminum construction makes TRACKALPHA-PRO ideal for use with medium to large-size industrial machine tools and for use in wet environments. These 120 VAC-rated, high-power LED lights provide intense, uniform lighting, with up to a 4,600-lumen output (100 lumens per watt). They come with a standard bracket mount that allows for angle adjustments. Optional TACLIP mounts (sold separately) provide for extra sturdy, vibration-resistant installations.

Automation-Direct adds CCEA TRACK-ALPHA-PRO series LED light bars to expand their offering of industrial LED fixtures. Their rugged industrial-grade anodized aluminum construction makes TRACKALPHA-PRO ideal for use with medium to large-size industrial machine tools and for use in wet environments. These 120 VAC-rated, high-power LED lights provide intense, uniform lighting, with up to a 4,600-lumen output (100 lumens per watt). They come with a standard bracket mount that allows for angle adjustments. Optional TACLIP mounts (sold separately) provide for extra sturdy, vibration-resistant installations.

Learn more.

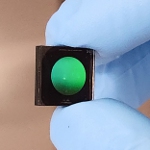

World's first metalens fisheye camera

2Pi Optics has begun commercial-ization of the first fisheye camera based on the company's proprietary metalens technology -- a breakthrough for electronics design engineers and product managers striving to miniaturize the tiny digital cameras used in advanced driver-assistance systems (ADAS), AR/VR, UAVs, robotics, and other industrial applications. This camera can operate at different wavelengths -- from visible, to near IR, to longer IR -- and is claimed to "outperform conventional refractive, wide-FOV optics in all areas: size, weight, performance, and cost."

2Pi Optics has begun commercial-ization of the first fisheye camera based on the company's proprietary metalens technology -- a breakthrough for electronics design engineers and product managers striving to miniaturize the tiny digital cameras used in advanced driver-assistance systems (ADAS), AR/VR, UAVs, robotics, and other industrial applications. This camera can operate at different wavelengths -- from visible, to near IR, to longer IR -- and is claimed to "outperform conventional refractive, wide-FOV optics in all areas: size, weight, performance, and cost."

Learn more.

Orbex offers two fiber optic rotary joint solutions

Orbex Group announces its 700 Series of fiber optic rotary joint (FORJ) assemblies, supporting either single or multi-mode operation ideal for high-speed digital transmission over long distances. Wavelengths available are 1,310 or 1,550 nm. Applications include marine cable reels, wind turbines, robotics, and high-def video transmission. Both options feature an outer diameter of 7 mm for installation in tight spaces. Construction includes a stainless steel housing.

Orbex Group announces its 700 Series of fiber optic rotary joint (FORJ) assemblies, supporting either single or multi-mode operation ideal for high-speed digital transmission over long distances. Wavelengths available are 1,310 or 1,550 nm. Applications include marine cable reels, wind turbines, robotics, and high-def video transmission. Both options feature an outer diameter of 7 mm for installation in tight spaces. Construction includes a stainless steel housing.

Learn more.

Mini tunnel magneto-resistance effect sensors

Littelfuse has released its highly anticipated 54100 and 54140 mini Tunnel Magneto-Resistance (TMR) effect sensors, offering unmatched sensitivity and power efficiency. The key differentiator is their remarkable sensitivity and 100x improvement in power efficiency compared to Hall Effect sensors. They are well suited for applications in position and limit sensing, RPM measurement, brushless DC motor commutation, and more in various markets including appliances, home and building automation, and the industrial sectors.

Littelfuse has released its highly anticipated 54100 and 54140 mini Tunnel Magneto-Resistance (TMR) effect sensors, offering unmatched sensitivity and power efficiency. The key differentiator is their remarkable sensitivity and 100x improvement in power efficiency compared to Hall Effect sensors. They are well suited for applications in position and limit sensing, RPM measurement, brushless DC motor commutation, and more in various markets including appliances, home and building automation, and the industrial sectors.

Learn more.

Panasonic solar and EV components available from Newark

Newark has added Panasonic Industry's solar inverters and EV charging system components to their power portfolio. These best-in-class products help designers meet the growing global demand for sustainable and renewable energy mobility systems. Offerings include film capacitors, power inductors, anti-surge thick film chip resistors, graphite thermal interface materials, power relays, capacitors, and wireless modules.

Newark has added Panasonic Industry's solar inverters and EV charging system components to their power portfolio. These best-in-class products help designers meet the growing global demand for sustainable and renewable energy mobility systems. Offerings include film capacitors, power inductors, anti-surge thick film chip resistors, graphite thermal interface materials, power relays, capacitors, and wireless modules.

Learn more.

Army to streamline Network Integration Evaluation process for industry, small businesses

By Claire Heininger, U.S. Army

The Army is refining its buying methods and reaching out to small businesses in order to smooth the path for industry to participate in the Network Integration Evaluations.

Vehicles equipped with Warfighter Information Network-Tactical Increment 2 for on-the-move communications capability prepared for the Network Integration Evaluation 12.2 at Fort Bliss, Texas, in spring 2012. With three Network Integration Evaluations now completed, the Army is leveraging that experience and applying industry feedback in order to improve the process and its outcomes.[Photo Credit: Amy Walker, U.S. Army]

Industry support is crucial to the success of the Network Integration Evaluations, known as NIEs, and Agile Process, which solicit mature technologies from both large and small businesses and put them to the test in an operational environment to determine whether they fill the Army's hardware and software needs. With three NIEs now completed, the Army is leveraging that experience and applying industry feedback in order to improve the process and its outcomes.

"We're bringing in technologies that would normally take six or seven years for us to get in the hands of Soldiers, and now are taking months," said Brig. Gen. Daniel Hughes, director of Army System of Systems Integration. "The Agile Process allows us to evaluate technologies more quickly; now we are streamlining the procurement process so we can reward those systems that are successful and field them as part of the Army network."

The service is now finalizing a plan to incorporate successful industry systems into Army materiel portfolios by aligning them with existing Programs of Record. The Army is also building a Request for Proposal, or RFP, solicitation to establish a formal mechanism to procure systems that show promise out of the NIE.

The initial RFP, in addition to continued Sources Sought notices, targeted for release this fall, will result in an NIE support contract award for NIE 14.1 with an option for production quantities. This will allow the Army to execute a contract option to procure production material to quickly field to Soldiers.

"While the Army has already bought certain technologies out of the NIE process, we are now taking a more systemic approach that will provide industry more visibility on how to achieve a tangible return on investment," Hughes said.

For small businesses in particular, participating in a massive Army field exercise and multi-phase process leading up to it can be a daunting proposition. The Army can assist small businesses by providing funding to offset labor and Field Service Representative costs and to produce additional system quantities needed for evaluation beyond what they can afford to bring themselves.

"From an Army point of view, small business brings a wealth of knowledge and technology," said Lt. Col. Carlos Wiley, who leads pre-NIE Lab Based Risk Reduction efforts that integrate government and industry systems prior to their field tryout with Soldiers. "They can be very agile in responding to and fixing any issues with their systems. So it's critical that we keep fostering small business to get out and look at our capability gaps to try and find a solution."

For example, during lab preparation for the October NIE 13.1 a small company was very responsive when engineers discovered integration problems between its technology and existing Army radios, Wiley said.

"Initially when we had them come in, we did not believe that they would be mature enough to be able to support and go through NIE 13.1," he said. "But every time there was an issue, they were there, and now they're ready to go in NIE."

The Army is also encouraging small businesses to bring forward their technologies in earlier stages of development so they are better prepared to participate in the Agile Process. Through avenues such as Cooperative Research and Development Agreements, known as CRADAs, or Test Service Agreements, or TSAs, small businesses can obtain detailed information on existing Army systems and better understand how they might modify their systems in order to integrate into the Army network, said Scott Newman, program director for Systems Engineering and Integration for the Army Communications-Electronics Research, Development and Engineering Center.

"Once they get this information and can integrate with the network baseline, they provide great technology that can benefit Army programs," he said.

Launched in June 2011, the NIEs are semi-annual evaluations designed to quickly integrate and mature the Army's tactical communications network -- the service's top modernization priority. The events assess new network capabilities from government and industry with an operational brigade combat team to determine whether they perform as needed, conform to the network architecture, and are interoperable with existing systems.

Industry interest has increased significantly since the NIEs began. In response to Sources Sought notices issued by the Army, 43 industry candidates responded for NIE 12.1, 105 responded for NIE 12.2 and 146 responded for NIE 13.1. Small businesses have been represented each time, with a peak of eight small business solutions among the 24 industry candidate systems selected to participate in NIE 12.2.

In addition to Army-hosted Industry Day outreach seminars, small businesses have actively approached the Army at forums such as conferences and other industry events seeking information on how to participate in NIEs. One such company submitted a successful candidate during NIE 12.2 and is now participating as a carryover system in NIE 13.1.

One small company that participated in NIE 12.2 was Ringtail Design, a 15-person business that contributed software known as Common Tactical Vision. The touch screen-based tool, used for mission command planning at various echelons across the brigade combat team, received positive feedback from Soldiers during the five-week evaluation.

Ringtail CEO Jeff Carpenter called the user feedback "extremely valuable" and said that with a small staff, Ringtail engineers could interact directly with Soldiers to implement changes within as little as a week. However, he has been disappointed that the Army has not moved more quickly to act on those positive results from NIE and adopt the system for fielding.

"I was hopeful that there would've been more traction," Carpenter said. "It is a lot of time, it is a lot of commitment, and it costs a lot of money to participate."

Army leaders acknowledge such concerns and said they will continue to work aggressively to ensure the NIEs achieve their potential as a way to rapidly bring industry innovation into the Army portfolio.

"The NIE is an evolving and adaptive process -- the first event occurred just over one year ago," Hughes said. "The Army considers NIE participation to be an opportunity for industry to obtain first-hand feedback from its Soldier-customers in an environment not available elsewhere. Industry has provided numerous examples of how it was able to make improvements to its products based on this feedback, which comes at notable cost to the Army as well. NIE participation is a partnership to which the Army and industry both contribute."

Published August 2012

Rate this article

View our terms of use and privacy policy